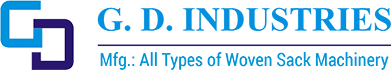

Owing the immense popularity of our tape stretching plant in the industries, we present the indispensable part of this tape stretching plant called hot plate. This hot plate is manufactured implementing the latest technologies in order to make it efficient and effective in its objective and ultimately magnifies the productivity of the respective tape stretching plant.

This hot plate for tape stretching plant is grabbing the high number of consumers for its efficacy and availability at comparatively low cost. No matter, what size of hot plate one is desired for, our tech savvy team of the engineers is ready to develop with all the zeal and surpass your expectation at farthest, apparent from swift raising in its demand since the introduction. Our hot plate for tape stretching plant is compatible with all types of plastic material, incorporating HDPE, PP, PVC, BOPP, LDPE, etc.

| MODEL | GDLAM B1000 | GDLAM B1700 |

|---|---|---|

| SCREW DIA MM | 70 | 80 |

| DIE WIDTH MM | 1000 | 1700 |

| MAX COATING WIDTH MM | 850 | 1550 |

| OUT PUT KG/HR | 260-280 | 320-360 |

| MAX LINE SPEED MPM | 110 | 110 |

| COATING THICKNESS MICRON | 20-100 | 20-100 |